Researchers unveiled a groundbreaking application of Sentinel-1 InSAR technology for monitoring tailings dams and predicting geotechnical instability in April 2024. Earlier this year, ETH Zurich research challenged the assumption of inherent safety in closed dams, revealing the growth of slip surfaces in decommissioned tailings dams. The materials sector faces significant challenges, with tailings dams exhibiting a 1.2% failure rate over the past century, far exceeding water storage dams. To address risks, entities must adopt a comprehensive approach integrating technology, rigorous training, and proactive community engagement throughout the TSF lifecycle.

Improving tailings management with technology and training

Empowering employees and contractors: Implementing cutting-edge TSF monitoring tech and comprehensive training programs

People: Social & Governance impacts

Materials (all industries)

AT A GLANCE

Advanced technologies like Sentinel-1 InSAR are revolutionising tailings storage facility monitoring.

This addresses the critical 1.2% failure rate of TSFs which is significantly higher than water storage dams.

Comprehensive approaches integrating technology, training and community engagement are essential for mitigating TSF risks and ensuring operational sustainability.

Advanced TSF technology

Advanced TSF monitoring technologies, such as Sentinel-1 InSAR and database-driven quantitative risk assessment approaches, are revolutionising real-time surveillance and predictive capabilities for tailings facilities, offering crucial insights for both active management and long-term closure planning. A comprehensive study published in November 2024 highlights historical failure incidents of tailings storage facilities in China and suggests a database-driven quantitative risk assessment approach.

Global disclosure standards

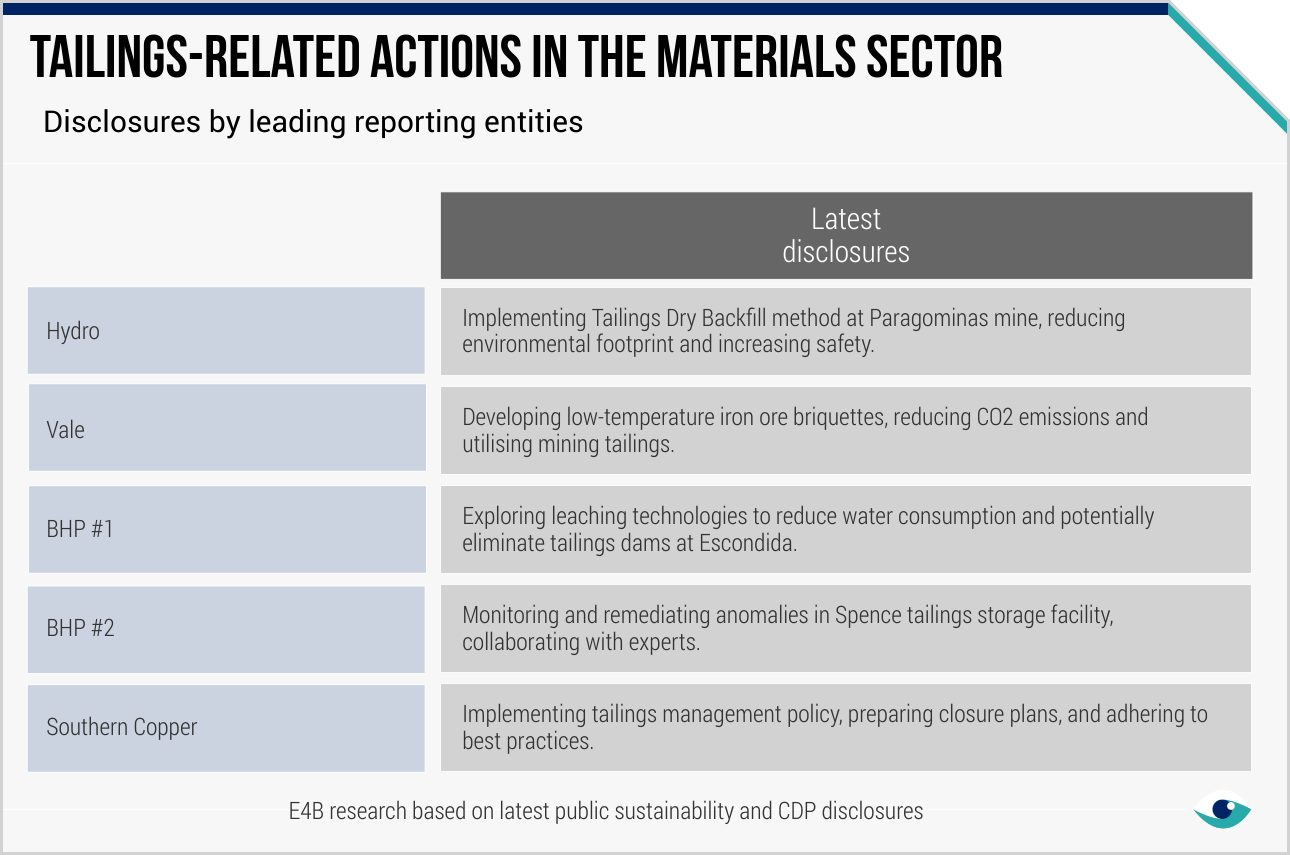

The Global Industry Standard on Tailings Management (GISTM) is driving significant changes in the industry, with major mining entities committing to its implementation and public disclosure of TSF information, though still vulnerable to criticism for not going far enough. Members of the ICMM are mandated to implement the GISTM, with facilities categorised as having 'Extreme' or 'Very high' potential consequences of failure required to conform to the standard within three years of 5th August 2020 and all other facilities within five years.

Staff & contractor training

Mining entities are adopting preventive approaches to safety issues by enhancing Critical Risk Registries, improving monitoring compliance levels and promoting visibility of risks such as tailings dam failures across all organisational tiers. Key measures implemented by materials entities include adherence to and continuous improvement of tailings systems policies, development of closure plans for all active tailings dams and decommissioning of inactive tailings dams, waste rock piles and slag heaps, in accordance with industry best practices.

Community engagement

Proactive community engagement in tailings management is becoming increasingly critical, as evidenced by recent opposition to tailings transportation plans. In October 2024, local government bodies in Ontario, Canada, formally opposed a proposal to transport niobium mine tailings, citing concerns about potential environmental and health impacts, particularly regarding drinking water sources.

FURTHER READING

- Application of Sentinel-1 InSAR to monitor tailings (Env. Science, Engineering, Geology - 2024)

- Global Industry Standard on Tailings Management (GISTM) (Global Tailings Review)

- Tailings facility disclosures reveal stability risks (Scientific Reports - 2021)